BAGS DECORATION METHODS

The following decoration/printing options are available to help to create your custom made and bespoke promotional bags, including but not limited to, holdalls, duffel bags, conference bags, laptop sleeves, drawstring bags, backpacks, laptop bags, trolleys, and travel bags. The printing methods and designs will be confirmed prior to production or personalisation.

Screen Printing On Bags

The most popular technique, and oldest decorating method for printing your logos and designs on your promotional bags, including conference and drawstring bags, is the screen printing method. The process starts by creating a stencil of your design and applying this stencil onto a fine mesh.

Each created colour screen/mesh (stencil),) is coated in emulsion and exposed to light, which takes approximately 30 minutes to prepare. Once prepared, a screen can be used for thousands of prints -making it a great method for small and large quantities!

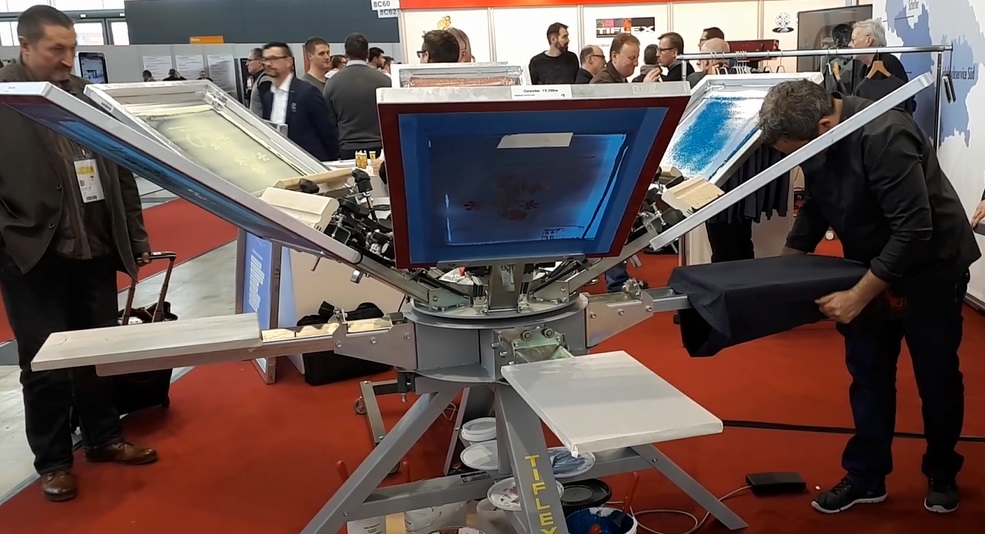

The coloured ink is applied such that it is forced through the mesh and onto the product while it is lying flat (each colour is applied using a different mesh/stencil). Typically using a carousel screen printer, the bag material is placed in a fixed position, and different meshes with different colours (6-8 maximum) are rotated into position and applied to the material.

In terms of cost efficiencies, screen printing is ideal for more than 200 items. Ideally printing is performed on the fabric pieces during the production stage rather than on finished products. This process is faster and cheaper for our customers, and in the event of any mistakes or misprinting, only the affected piece of fabric is discarded, rather than the whole bag.

In order to improve the quality of our screen printed bags, prior to printing we apply a transparent layer to guarantee a smooth working area. This enables us to create more precise and detailed logos with multiple colours.

|

|

|

| Screen printing on bags, done on the piece of fabric before the stitching. The ink moves through the mesh to the fabric. |

Screen printing during the bags’ production (on the fabric pieces) is faster and cheaper compare to printing on completed bags. | Carousel for screen printing on bags and T-Shirts. Usually, screen printing is done with 1 to 4 colours. The screen printing carousel can be used with bags, before or after the production. |

|

|

|

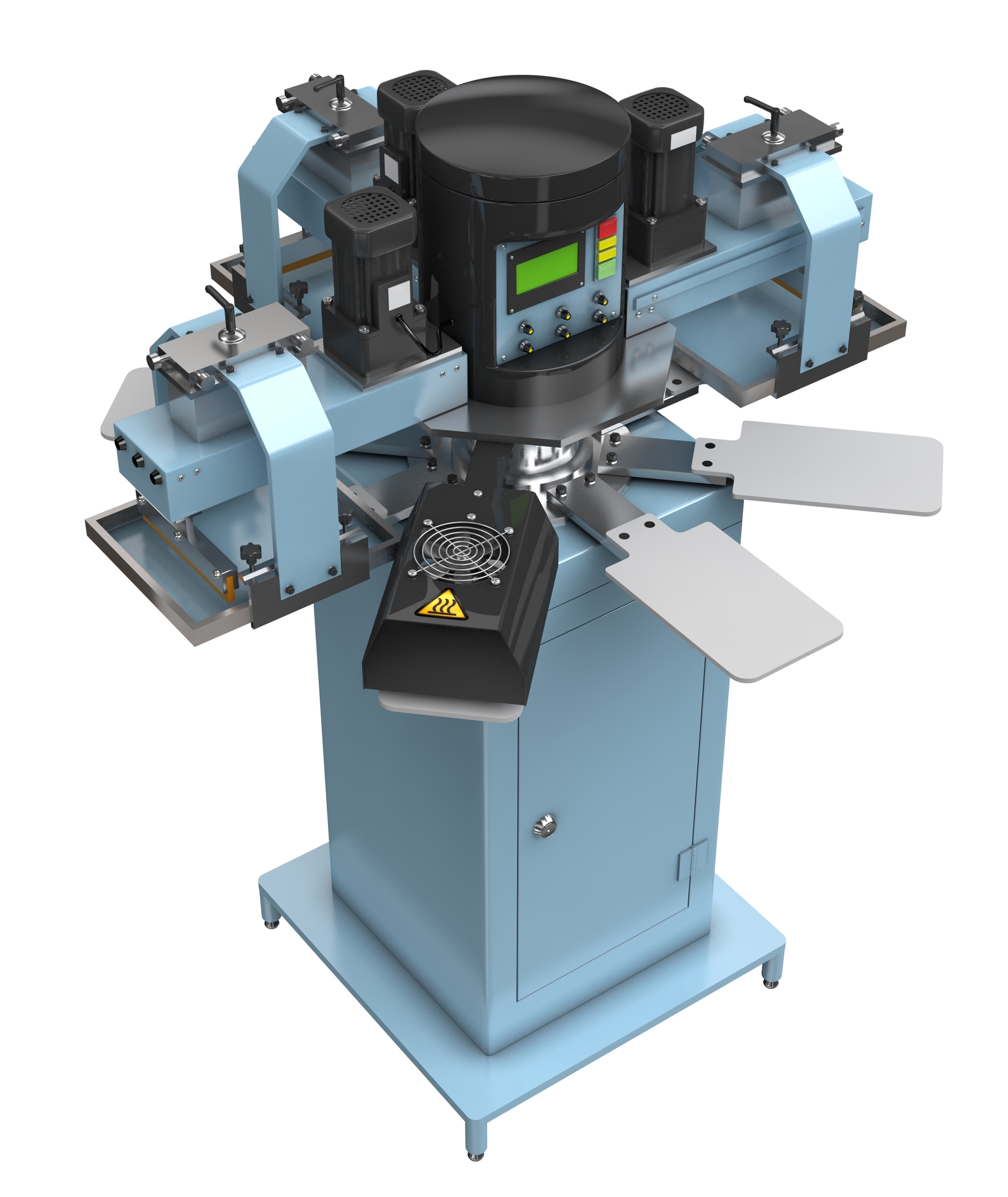

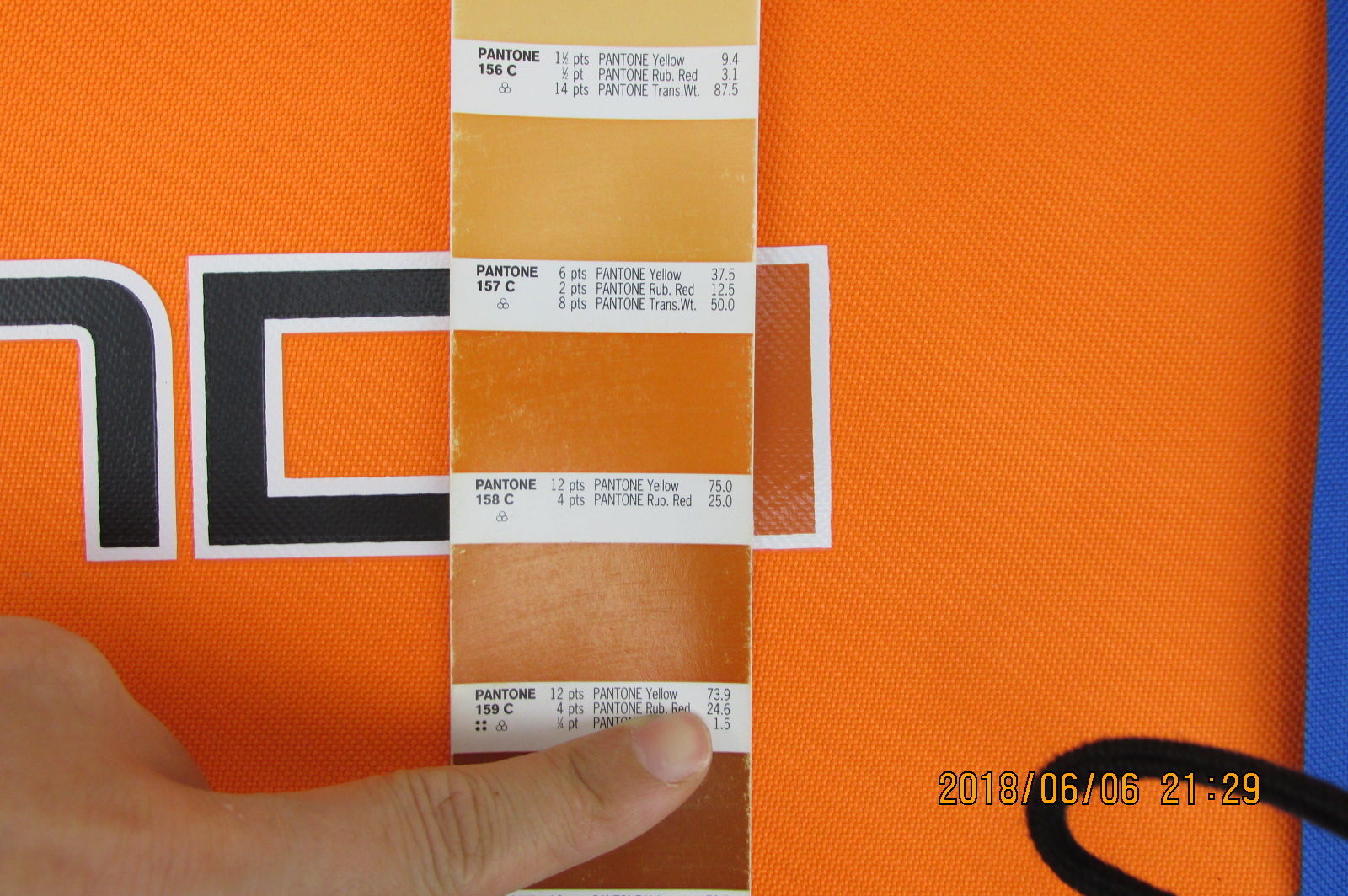

| Screen printing on bags – automatic printing press carousel | Screen printing on bags - pantone colour matching | Screen printing on bags - application of the ink |

Sublimation Printing On Bags

Another popular technique for decorating customised bags is sublimation printing. Sublimation is the process of a substance converting from a solid to a gas state without ever being a liquid - and sublimation printing uses this to embed ink into a fabric.

The process begins with a digitally printed mirror image of your logo or design, produced on a piece of paper which has a specially coated transfer material (not regular printing paper). The digital printer uses red, green and blue (RGB) as well as greyscale colours, and the section of the bag to which the image is transferred originally begins as a white fabric (white background).

The transfer paper, which has the pattern of the desired printed logo, is placed in a heat press with the bag material and exposed to temperatures of 180-230⁰C, allowing the conversion of the ink from a solid to a gas state. While in this gas state, the ink permeates the fibres of the material, which solidifies on cooling and becomes intertwined with the fabric. The effect is permanent and when correctly performed the image will not experience any deterioration except that associated with the material itself.

With sublimation, the number of colours that can be applied to the bag is limitless (4 Colour Process Printing). A disadvantage is, that the background must be white or off-white.

This process is excellent for the use on materials such as Polyester and other plastic based materials (including nylon) which can be used to create backpacks, drawstring bags, duffel bags, holdalls, sports bags, travel bags, conference bags and many other promotional products with your logo and design!

|

|

|

|

1. Printing the logo/design, mirror image, on special paper for Sublimation Printing. |

2. Cutting the printed papers with the logo. | 3. Printing before the bags’ production – the Sublimation Printing is applying on pieces of fabric, in hot presser. Possible – few printings together. |

|

|

|

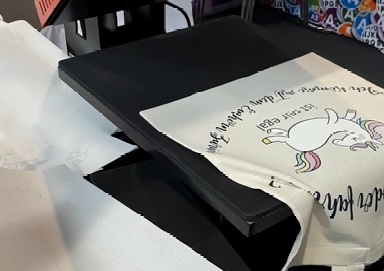

| 3 B. After the bags’ production, Sublimation Printing can be done in hot presser, one by one. | 4. Sublimation Printing on a cotton bag. | 5. Sublimation Printing on a kids backpack. |

Digital Transfer Print (Heat Transfer Printing) On Bags

If you require greater detail in your logo, brand or design than screen printing and sublimation can provide, such as when the logo/artwork has overlapping colours, then digital transfer printing is a good option.

By cutting out the design on a special vinyl material, the whole design is captured in one application. The vinyl is placed over the material, and using a special heat press at high temperatures (about 160⁰C), the design is transferred to the bag material.

The number of colours is unlimited, and the printed resolution is higher than all the other printing options that we offer.

However, the process of Heat Transfer leaves a thin vinyl layer on the product, with the same shape as the outline of the logo.

This technique is great for bags such as sports bags that require bright and bold club logos with finer detail. This method is cost effective for small and large orders.

We will confirm the look of the final product prior to mass production.

| Stickers for Heat Transfer Printing, before applying on the bags. | Hot presser to apply Heat Transfer Printing | Typical press machine for Heat Transfer Printing. |

| Digital Heat Transfer Printing - stickers | Digital Heat Transfer Printing - presser | Digital Heat Transfer on Bags 03 - heat-press-machine |

| A drawstring Backpacks with Digital Transfer Print (Heat Transfer Printing). | A drawstring Backpacks with Digital Transfer Print (Heat Transfer Printing). | A bag with Digital Transfer Print (Heat Transfer Printing). |

| Digital Heat Transfer on Bags 04 - Drawstring Backpack 1 | Digital Heat Transfer on Bags 05 - Drawstring Backpack 2 | Digital Heat Transfer on Bags 06 - sample on laptop bag |

Embroidery On Bags

Embroidery is a high-quality and impressive method to decorate bags and other textile items, and it is the favourite one among many.

The details/pattern of your design is initially reviewed and read by the software and an automated ‘stitching plan’ is created.

Then, the bag material is fixed in position using a ring, and using our computerised sewing machines, the design is embroidered onto the fabric.

The stitch colours, density and finishing can all be varied, providing a 3D finish to the final logo. It can add greater texture to your logo and be used to highlight different parts of your design.

Common logo embroidery has between 2,000 to 6,000 stitches, with one to eight colours.

The area used for embroidery of logos, brands and designs is usually the smallest of all our printing options.

With our stocked products there is no minimum quantity. In most cases, there is, however, a small fee for the stitching program.

With this technique we accept a minimum order quantity, for specially produced items, of approximately 500 items.

It is better to print/embroidery during the bag/product manufacture, i.e. on the individual fabric pieces rather than the final product. This way the process is cheaper, and access to the material is easier, enabling greater flexibility in the positioning of the design and a higher quality. Additionally, should any mistakes or errors occur, only part of the bag has to be discarded rather than the entire product.

| Embroidery machine for bags, fabrics and garments. | Embroidery on fabric and bags. Stitching machine. | A bag with Embroidery logo. |

| Embroidery on Bags 01 - stitching machine | Embroidery on Bags 02 - stitching machine | Embroidery on Bags 03 - sample on laptop bag |

| Embroidery on Bags – sample of embroidery | Embroidery on Bags – backpack 1 | Embroidery on Bags – backpack 2 |

| Embroidery on Bags 04 - sample 2 | Embroidery on Bags 05 - backpack 1 | Embroidery on Bags 06 – backpack 2 |

Printing Options for Our Popular Products

| Our Popular Items | Sublimation Printing | Transfer Printing | Screen Printing | Embroidery |

| Backpack | V | V | V | V |

| Drawstring Backpacks | V | V | V | X |

| Cooler Lunch Bags | V | X | V | X |

| Laptop Backpack | V | V | V | V |